Overview

The electric vehicle revolution demands constant innovation in powertrain technology, with a key trend being the shift towards higher voltage battery systems (now 800V and beyond). This transition necessitates a critical look at electric motor design, where insulation materials become paramount. Specifically, the insulation of magnet wires in stator windings faces increased electrical stresses.

Electric motors have a long tradition with standard materials being deployed for insulating the magnet wires used in the stators of an electric engine. As modern e-drive trains operate at 800 V or higher, the requirements for the insulation material are changing. In high-voltage EVs, superior dielectric strength and partial discharge resistance are essential for safe and reliable operation. Furthermore, high-performing insulation contributes to lower operational costs by minimizing energy losses and preventing failures.

Crucially, modern insulation materials with enhanced thermal conductivity enable the design of lighter and more compact motors. Efficient heat dissipation allows for higher power densities, directly impacting vehicle weight and size – key factors in extending driving range. By enabling higher voltage systems and contributing to lighter, more efficient motors, advanced insulation plays a vital role in achieving the core goals of the EV industry: longer range and quicker charging times.

Neoflon™ PFA is an excellent material candidate to help e-drive trains perform better, more efficient at reduced operating costs. Moreover, the use of Neoflon™ PFA will also provide a sustainable solution over enamel wire coatings with a full recycle potential.

Reduced cost

Reduced size

Improved efficiency

Longevity

Recyclable

Sustainable

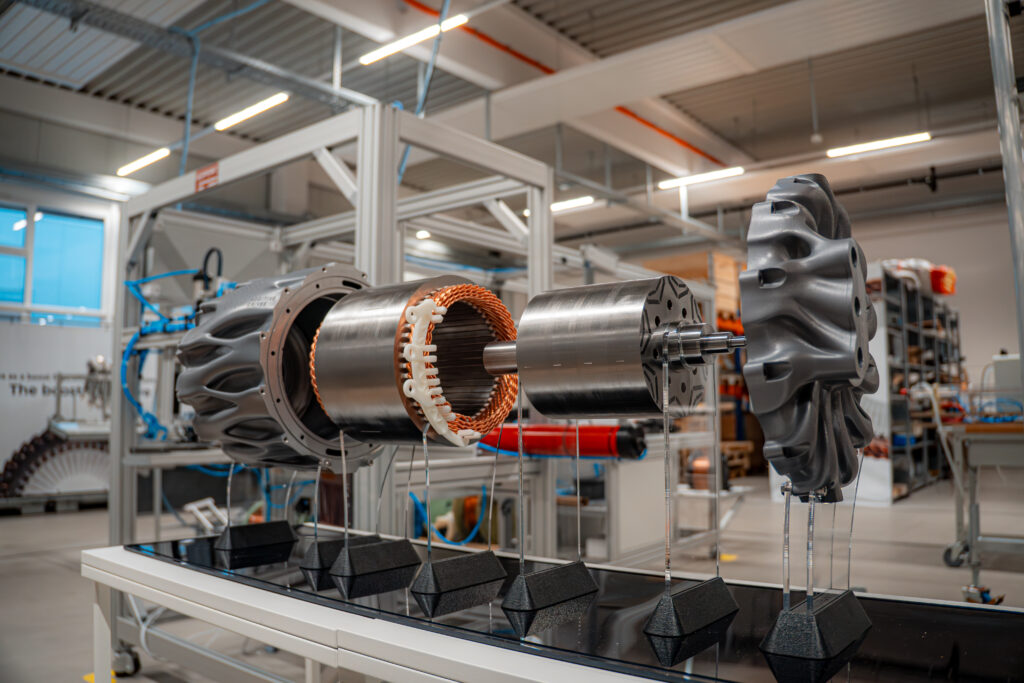

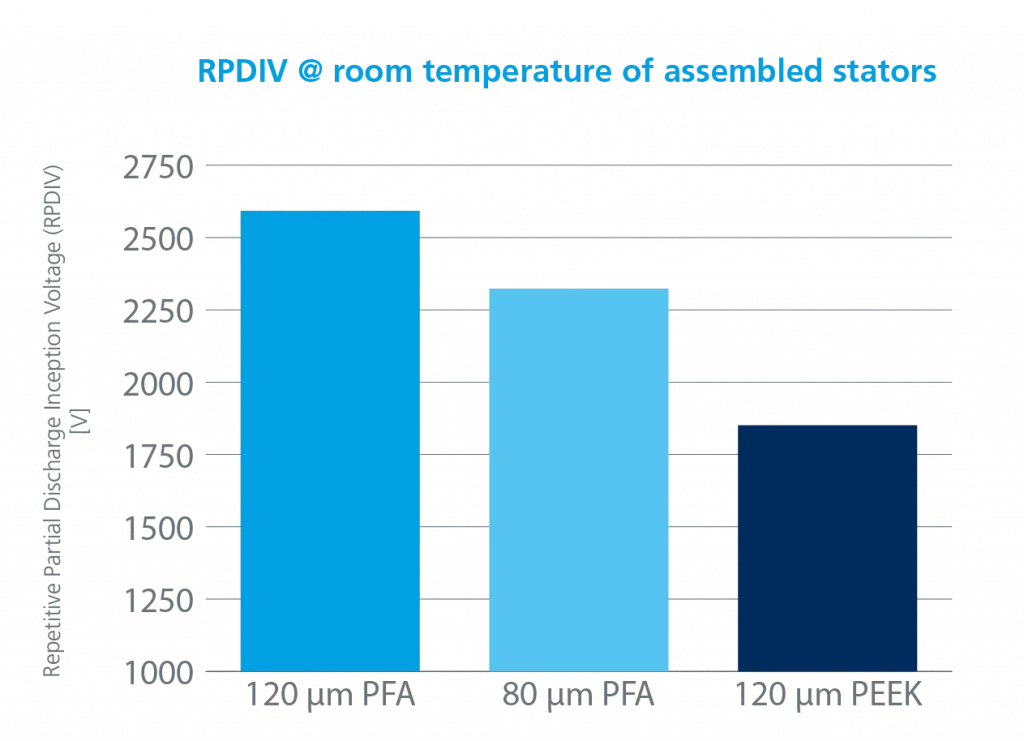

By investing in the research and development of innovative E-Powertrain Materials, Daikin is committed to drive the advancement of electric engines across various sectors, paving the way for a more sustainable and electrified future. During the last years we have worked with collaborative partners in the industry to prove the concept of using PFA fluoropolymer for 800 V+ e-motors. Extensive testing at wire and stator level demonstrated the superiority of PFA resin coated magnet wires, outperforming any known insulating material – enamel, or extruded – during Partial Discharge Inception Voltage (PDIV) functional testing. Its outstanding dielectric permittivity is contributing to an impressive performance enabling a significant reduction of insulation coating layer thickness while meeting stringent automotive requirements on PDIV. The additional benefit of the reduced insulation thickness is the increased copper fill factor, which directly boosts the power density.

The highest PDIV level is demonstrated in the two graphs below. It enables thinner insulation layer thickness at the copper wire and results in efficiency gains from 2 to 6%, and continuous performance gains above 10%.

Emerging aviation applications

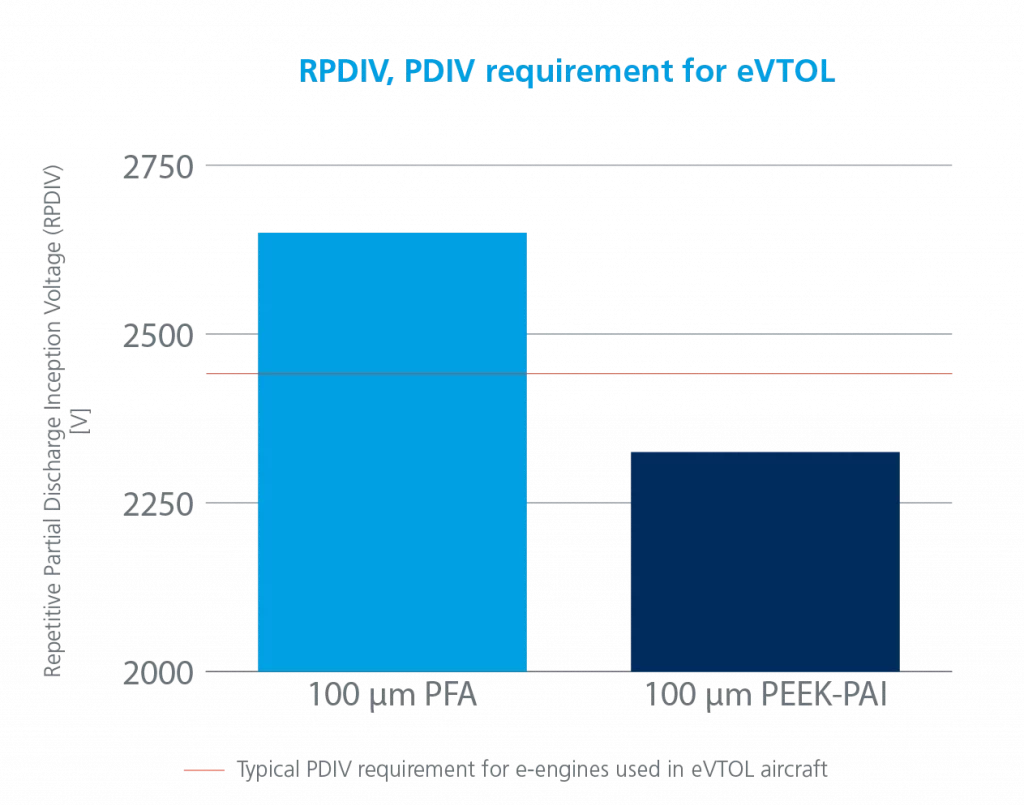

eVTOL (electric Vertical Take-off and Landing) are adopting the high voltage battery technology fast, following battery-electric vehicles and heavy-duty trucks.

The higher altitudes that eVTOL aircraft operate in require further improved PDIV resistant materials. PFA resin has a Partial Discharge Resistance of ≥ 35 V/µ, which is 60% higher than the incumbent material technology used. This makes it a suitable candidate insulation material for the magnet wire used in the electric motors of eVTOL aircraft. The use of 800V+ technology in eVTOL aircraft can also lead to reduced motor size and weight, increased power and improved motor efficiency.