DAI-EL Properties & Benefits

Daikin’s fluoroelastomers – DAI-EL – are designed to achieve the highest requirements in extreme environments. This includes high temperatures in combination with contact to fuel, diesel and all kinds of media.

DAI-EL’s very low permeation rate allows components to meet current environmental regulations. A sophisticated polymer design allows stable extrusion and molding processes for all kinds of technical rubber articles like O-rings, seals and fuel / turbocharger hoses.

Properties

Free of fluorinated emulsifiers

Heat & fuel resistance

Very low permeation rate

High flexibility

Excellent processability

Benefits

Helps reach emissions regulation targets

Allows for stable extrusion and molding processes

Long-term operability

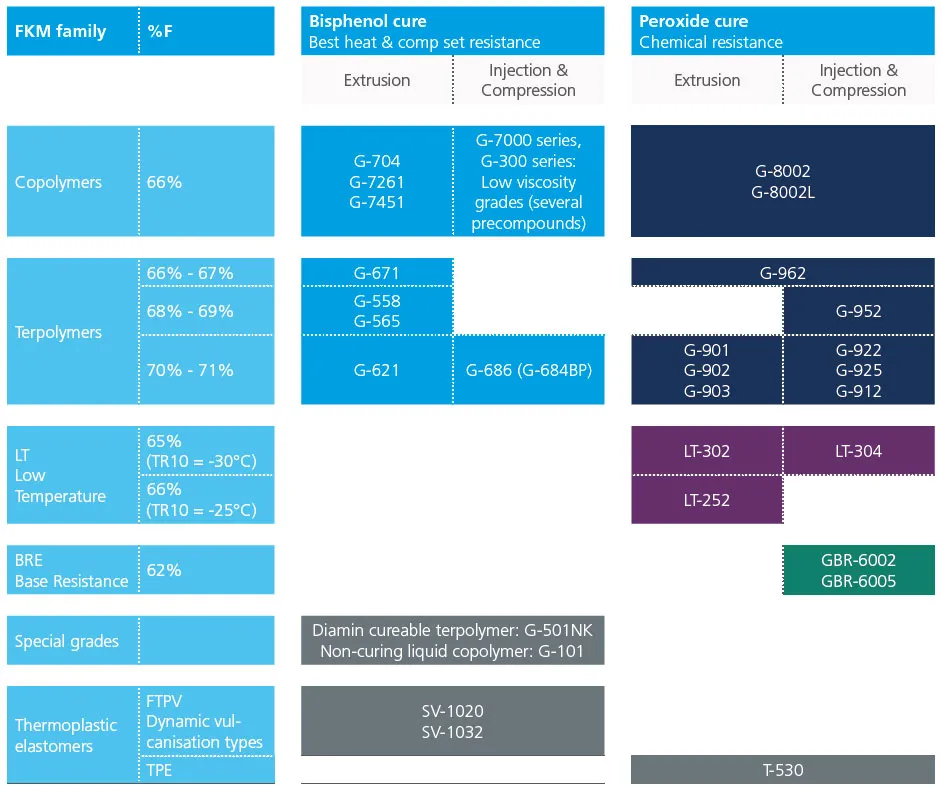

DAI-EL Fluoroelastomers Portfolio

Daikin offers the most complete portfolio of Fluoroelastomers products in the world today. From low Mooney materials to high performance peroxide curable products, Daikin FKM technologies are designed to perform in a broad range of demanding service and processing environments.

When you choose DAI-EL, you select the highest quality Fluoroelastomer products. And you join our growing family of satisfied customers who benefit from excellent support of new applications development. Daikin is continuously striving to develop newer and better Fluoroelastomer technologies, and provide outstanding technical support for customers worldwide.

Our comprehensive FKM portfolio covers the full range of copolymers and terpolymers for bisphenol and peroxide curing. This includes:

– Bisphenol grades for a maximum of heat resistance and the lowest compression set within the DAI-EL product range,

– Peroxide curable grades for better acid resistance and overall mechanical properties,

– Low temperature (LT) FKM (Tg = -30°C),

– Base resistant fluoroelastomers (BRE) with superior mechanical properties to meet tomorrow’s requirements,

– Perfluoroelastomers with superior chemical resistance and high cleanliness,

– Series of fluoro-thermoplastic elastomers, F-TPV, that offers a unique combination of low permeation, low modulus (high flexibility), and excellent processability.

All Daikin elastomers are well recognized in the market for their excellent quality and processing behavior. Daikin’s philosophy combines technical material performance with dedicated technical and commercial service. Close cooperation and partnership with our customers is the key element for our current and future joint success.

DAI-EL Fluoroelastomers: Orientation Map

Technical support

Daikin provides extensive technical support in all major markets: automotive, aerospace, chemical and petrochemical industries.

The Technical Service (TS) for DAI-EL Fluoroelastomers is part of the global TS network of Daikin’s Chemical Division. Our TS team in the EU is integrated with the Daikin Chemical Europe Innovation Center in Dortmund, an integration that, among other advantages, provides faster access to analytical measurements.