Daikin Refrigerant News - Issue 1, 2021

Dear friends and partners of Daikin Chemicals,

First and foremost, let me wish you a happy new year! We hope you have had a peaceful end of the year and were able to unwind with your loved ones.

Also, please allow me to express a big Thank You to all of you for the subscription, positive feedback and the constructive suggestions regarding our new quarterly "Daikin Refrigerant News", which has reached us after the first edition in October. Today, I am pleased to introduce the newsletter’s second edition.

In 2020, a year that was full of challenges and hardships for all of us, we created the idea for this newsletter in order to help maintain our constant dialogue with you in a period of less personal meetings and industry events. The great feedback from you has reinforced our feeling that this was a positive step.

When we look ahead into 2021, we can see that our industry will continue dealing with the impact of the pandemic, but equally with many paradigm shifts in terms of global and EU policy, which we need to discuss and tackle together. We want to deal with topics such as the EU Green Deal or the European chemicals strategy together with you in 2021.

After all, the refrigerant industry sees itself as an important actor regarding the protection of the climate and wants to help boosting the economic recovery in 2021. Together with you, we are confident and optimistic that our industry will surpass these challenges. In fact, we are sure to come out stronger at the end of this phase than before.

Kind regards and enjoy reading

Your Tobias Bargsten

Business Manager Refrigerants Daikin Chemical Europe

F-gas Regulation & Phase-down process: What is new in 2021?

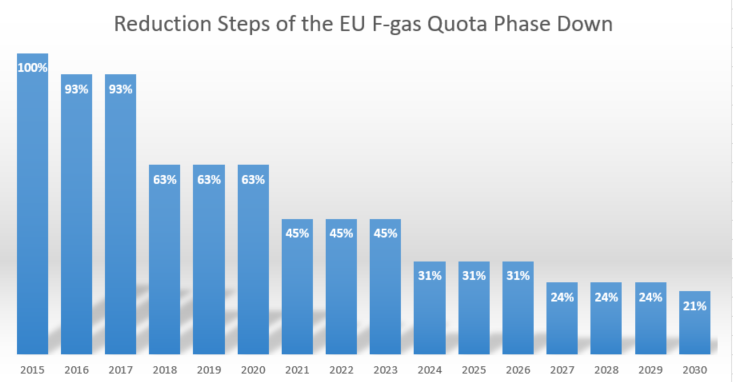

The third reduction stage of the phase-down process of the new F-gas regulation (Regulation (EU) No. 517/2014) is taking place in 2021. This means that the quota available for the production and import of F-gases drops to 45% of the 2015 value. Six years after the regulation came into force, less than half of the original quotas are now available to the EU market.

Less than half of the original quotas are now available to the EU market.

The strong increase in the number of registered quota holders also leads to a fragmentation of the total quota into many small "splinter" quotas. In 2021, the number of incumbent quota holders increased by almost 1,000 companies to 1,386 compared to 2018. Added to this are the newly registered so-called "New Entrant Quota Holders". Customers of dealers who have not yet optimized their product portfolio must expect a shortage of supply.

Brexit contributes to the reduction

But the reduction step is not the only cut in the quota: Brexit also contributes to the reduction of the EU quota, as all F-gas quantities that were placed on the UK market in the period 2015-2019 are now used to calculate the F-gas quota in the UK. So there is a division into F-gas quota of EU and GB.

For the placing on the market of pre-filled devices in Great Britain from now on, parallel to the EU F-gas regulation, the person placing the product on the market must have quota authorization, which he has received from a UK F-gas quota holder. The authorization process is similar to that of the EU: both quota holders and authorization recipients must both have a profile in the UK F-Gas portal. However, the registered companies themselves do not have access to their profiles. All transactions are carried out by the UK Environment Agency.

You can find more information about the F-Gas Quota in the UK here: https://www.gov.uk/government/collections/fluorinated-gas-f-gas-guidance-for-users-producers-and-traders#producing,-importing-or-exporting-f-gas-and-equipment

Daikin's efforts towards a circular economy

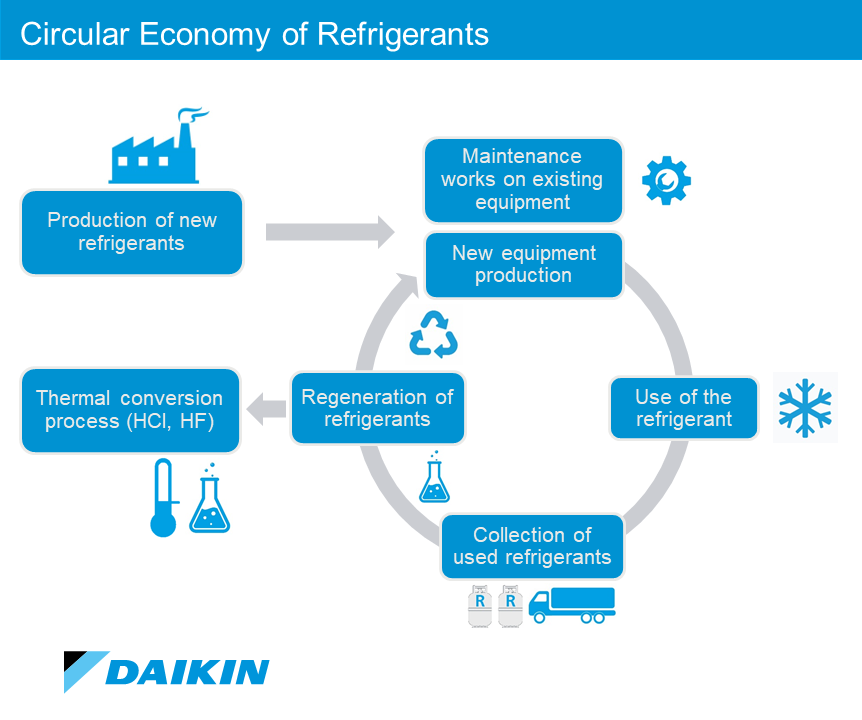

The new European Green Deal is putting in place clear guidelines for a Circular Economy. We as Daikin Refrigerants are committed to these principles and have put in place a manufacturing process that puts a focus on sustainability and circularity which we would like to illustrate to you.

At Daikin, our circular economy process starts in our factories with eco-friendly and low-emission machinery which produces refrigeration technology that uses 100% reclaimed refrigerants.

The next step is to recover the waste refrigerants coming from the maintenance works or decommissioning of the machines. These used to be destroyed or incinerated in the past. The waste refrigerants are collected in a special fleet of grey recovery cylinders and containers dedicated specially for this purpose to make the recovery easier for the installers and gas distributors.

Regeneration process

The regeneration takes place at our reclamation facility in Frankfurt. First, we conduct a cleaning process for the removal of oil, moisture, residue and inert gases. Afterwards we continue with a composition analysis to analyze if it is necessary to separate refrigerants at the separation plant or if a simple adjustment of the blend components is needed in order to bring these refrigerants back to the original virgin gas composition.

Refrigerants certification is standardized in the EU

Next, a certification under Virgin Refrigerants Standard (AHRI 700 Std. for EU Countries) follows before the refrigerants are put onto the market again for their reuse. They can be used not only in newly produced machines, but also for the maintenance and retrofit of existing machines. Through this certification analysis, Daikin ensures that our customers are guaranteed that the quality of their reclaimed refrigerants is exactly the same as that of virgin material.

Thermal conversion finishes the circularity loop

Last but not least, to encourage and close the whole circularity loop, recovered refrigerants that cannot be used again or reclaimed anymore go to our thermal conversion plant located in Frankfurt. There they are treated under high temperature and pressure. This turns them into acids, HF and HCI that are reused in the chemical industry. Thereby Daikin reduces waste to minimum levels. This process allows us to close the loop at the End of Life of the refrigerants.

Daikin and Honeywell team up for EU adoption of R-455A (Solstice L40X / Creard R-455A)

Daikin Chemical Europe and Honeywell have signed an agreement to distribute Honeywell’s Solstice L40X (R-455A). Daikin will sell the product as Creard R-455A for use in commercial refrigeration applications.

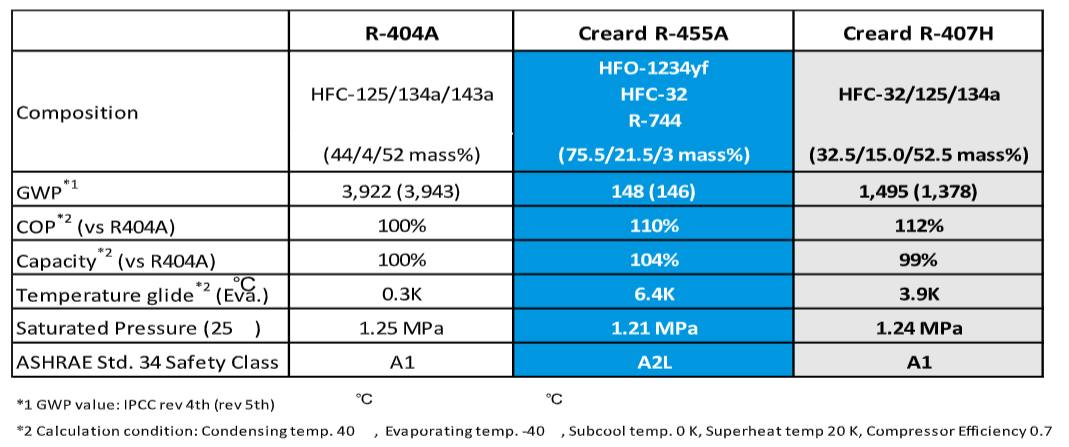

Daikin Chemical Europe selected R-455A to comply with the European F-Gas regulation by adopting a refrigerant with GWP below 150, which is the limit allowed in some commercial applications from January 1, 2022. The addition of R-455A also expands Daikin’s line-up of low global warming potential, high-performing refrigerants, which includes Creard R-407H, a replacement for legacy refrigerant R-404A.

R-455A is designed to replace R-404A, which was used in most existing commercial refrigeration systems. R-455A can be used in a range of new refrigeration equipment which is already qualified for use and with which refrigeration contractors are already familiar and trained to provide service. R-455A provides similar performance to R-404A, but offers 96% lower global warming potential and greater operating efficiency.

Daikin’s commitment is to provide our customers products that best fit their needs, and we identified R-455A from Honeywell as a safe and efficient replacement for R-404A as used in various commercial refrigeration applications. This product complements Creard R-407H in our product range and allows our customers to comply with stringent F-gas regulations while meeting growing energy efficiency needs.

R-455A is a mildly flammable, zeotropic refrigerant with an ultra-low GWP of 146, making it both F-Gas-ready and the safest A2L solution for commercial refrigeration applications like condensing units, monoblocks for cold and freezer rooms, heat pumps and chillers.

The refrigerant is qualified for use in many leading compressor technologies, including Tecumseh, Bitzer, Emerson, Boyard and Frascold – with many other compressor and condensing unit OEMs having also approved or in the final stages of testing, when integrated into appropriate system architectures. R-455A provides end users with a long-term, high-efficiency and cost-effective refrigeration solution.